A unique system that allows engineers to use their hands as their eyes when working in confined environments is being trialled for use within the aerospace industry and other sectors.

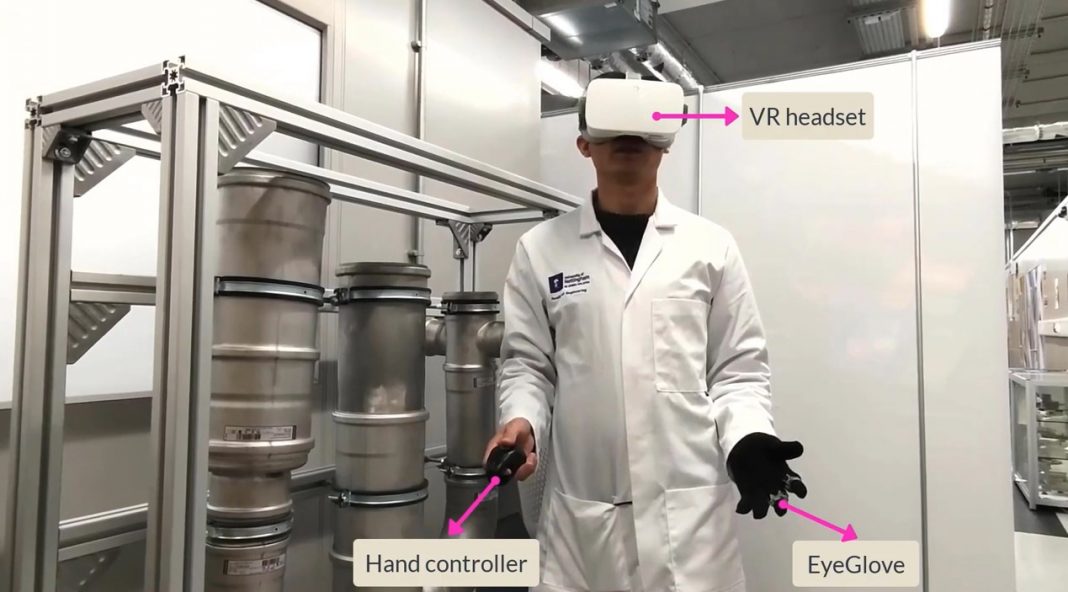

The wearable system, EyeGlove, has been developed by researchers based in the Rolls-Royce University Technology Centre (UTC) in Manufacturing and On-Wing Technology at the University of Nottingham. It contains a vision glove and a wearable display unit, including three tiny cameras, which gives the user’s hands the ability to ‘see’ inside cramped environments when conducting inspection and measurement tasks.

The inspection function uses one or two of the cameras to investigate restricted areas, while the measurement function utilises all three cameras and an artificial marker to assess object dimensions. The results are then presented on a wearable display for easy observation.

“Due to the incredibly restricted, and sometimes unsighted, environments we’re working in – for example, gas turbine engines – inspection and measurement tasks can’t be achieved using conventional rigid tools,” said Professor Dragos Axinte, director at the Rolls-Royce UTC in Manufacturing and On-Wing Technology.

Professor Axinte continued: “In some cases, borescope and endoscope cameras, or even robots, can be utilised to accomplish these tasks – but none of these are as flexible and dexterous as human hands. That’s why we’ve developed this novel wearable system, which allows the operator to undertake inspection and measurement tasks by using their hands as manipulators. In addition, each prototype of EyeGlove system is low-cost and affordable, costing less than £150, with further development, it has the potential to be a real gamechanger in the future.”

The research team led by Prof. Axinte and Dr. Xin Dong have created three different prototypes; two containing a disjointed camera configuration that offers high flexibility, and a third miniaturised version that configures all the cameras in one finger.

Preliminary testing was undertaken by six people, five of whom were beginners to the system and were given three opportunities to practice before measurements were taken. The results found that the average relative measurement error of five artificial targets was just 1.89%, with them giving the hardware a rating of 4.6 out of five.

“It was great to see how quickly participants adapted to using the EyeGlove system and to have received such positive feedback to this bespoke technology. Now we’ve successfully established the concept, our next step is to liaise with suppliers about the customisation, optimisation and, eventually, commercialisation of the EyeGlove system,” said Erhui Sun, research associate at the Rolls-Royce UTC in Manufacturing and On-Wing Technology, who developed the system.

EyeGlove has been funded through REINSTATE, a £21 million Aerospace Technology Institute funded project aimed at developing a portfolio of sensing, inspection and repair techniques for use within on-wing installed engines in the aerospace industry, as well as a variety of neighbouring sectors.

Andy Norton, REINSTATE programme manager and Rolls-Royce technology specialist, said: “The University of Nottingham continues to develop and demonstrate cutting-edge techniques that support our aerospace aftermarket business. EyeGlove is a fantastic example of how the REINSTATE team are working creatively and collaboratively to develop inspection methods for use across the product’s lifecycle to increase engine uptime, decrease cost and customer disruption, and improve through-life sustainability.

“While further maturation of the EyeGlove prototype is required, the team have achieved an important milestone through demonstration of key functionalities and its applicability within the aerospace sector.”